Purchasing a used excavator is a significant investment, and ensuring excavator’s engine and hydraulic system are in good condition is crucial. These components are the heart and veins of the machine, determining its performance, lifespan, and overall value. Here’s a detailed guide on what to check before making a purchase.

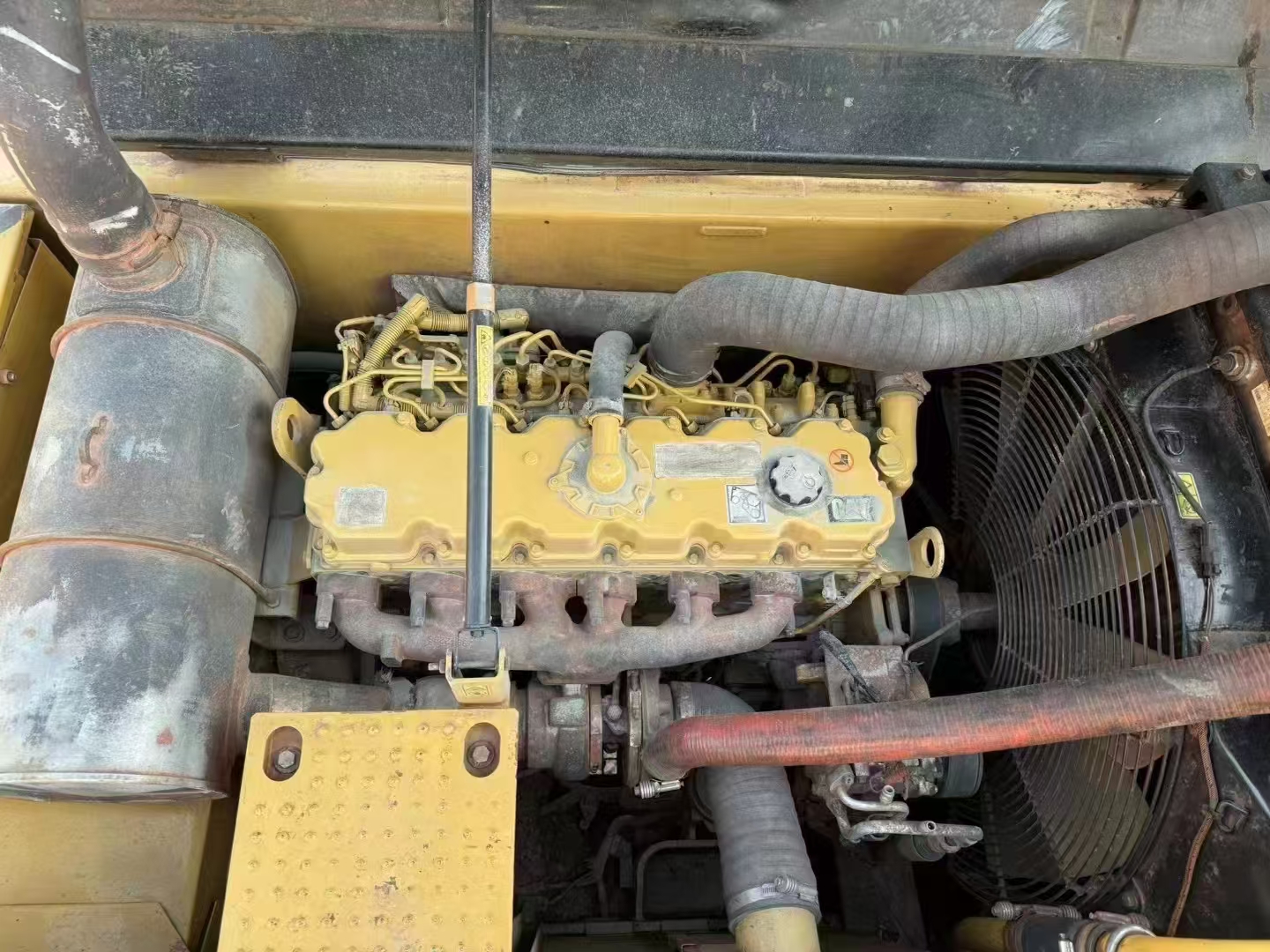

Inspecting the Excavator’s Engine

1. Start-Up and Idle Performance

A healthy engine should start smoothly without excessive cranking. Listen for any unusual sounds, such as knocking, clicking, or loud exhaust noise, which could indicate internal wear or damage. Allow the engine to idle and observe its stability—rough idling or sudden fluctuations in RPM can signal fuel system or sensor issues.

2. Exhaust Smoke Color

Different colors of exhaust smoke can indicate specific engine problems:

- Black smoke: Excessive fuel consumption, clogged air filter, or injector issues.

- White smoke: Possible coolant leakage into the combustion chamber due to a cracked head gasket or cylinder head.

- Blue smoke: Oil burning due to worn piston rings or valve seals.

A healthy excavator should emit minimal, clear exhaust under normal operating conditions.

3. Engine Oil Condition

Check the engine oil level and quality. Fresh oil should be clean and amber-colored, while excessively dark or gritty oil can indicate poor maintenance. Also, look for any milky or frothy consistency, which suggests coolant contamination, a serious issue that could lead to major engine failure.

4. Radiator and Cooling System

Overheating can lead to catastrophic engine damage. Inspect the radiator for leaks, corrosion, or blockages. Ensure the coolant is at the proper level and has a consistent color—rusty or murky coolant may indicate poor maintenance or internal corrosion. Run the engine for a while and check if it maintains a stable operating temperature.

5. Belts and Hoses

Examine all belts and hoses for cracks, wear, or leaks. A damaged belt can lead to alternator failure or coolant pump malfunction, while leaking hoses can reduce coolant or fuel efficiency, leading to potential breakdowns.

Checking the Hydraulic System

1. Hydraulic Pump and Pressure

The hydraulic pump powers all the movements of an excavator. Check for any unusual noises, such as whining or knocking sounds, which could indicate a failing pump. If possible, measure the hydraulic pressure to ensure it meets the manufacturer’s specifications.

2. Hydraulic Fluid Condition

Hydraulic fluid should be clean and free of contamination. Dirty, milky, or foamy fluid suggests the presence of water, air, or debris, which can damage hydraulic components. Also, check for proper fluid levels—low fluid levels can lead to cavitation and system failure.

3. Cylinder Condition

Inspect the hydraulic cylinders for leaks, dents, or damaged seals. Extended or retracted cylinders should hold their position without drifting. Any drift can indicate internal leakage, which can reduce the efficiency and power of the machine.

4. Hoses and Fittings

Examine all hydraulic hoses and connections for leaks, cracks, or bulging areas. High-pressure leaks can be dangerous and lead to performance issues. Ensure all fittings are secure and show no signs of wear or rust.

5. Boom, Stick, and Bucket Movements

Operate the boom, stick, and bucket through their full range of motion. Look for any slow responses, jerky movements, or hesitation, which can signal hydraulic pump or valve issues. The machine should respond smoothly without lag or unusual noises.

Additional Tips Before Finalizing Your Purchase

- Check Maintenance Records: A well-maintained excavator will have documented service history, including oil changes, filter replacements, and past repairs.

- Test Under Load: If possible, operate the excavator under load to assess how the engine and hydraulics perform under stress.

- Professional Inspection: If you’re unsure about evaluating these components, consider hiring a mechanic or specialist to conduct a detailed inspection.

Final Thoughts

A used excavator can be a great investment if properly inspected before purchase. Paying close attention to the engine and hydraulic system can save you from costly repairs and downtime. By following this guide, you can ensure that your chosen machine is in excellent working condition, maximizing its productivity and longevity.

Always take the time to perform a thorough inspection and, when in doubt, consult an expert to make a well-informed decision.

If you want a risk free and easy machinery purchase, check out list of available units in Shanghai Max Machine warehouse and contact us directly through WhatsApp or Instagram